Main features:

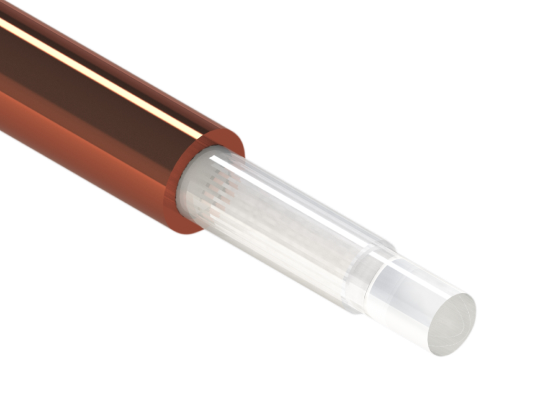

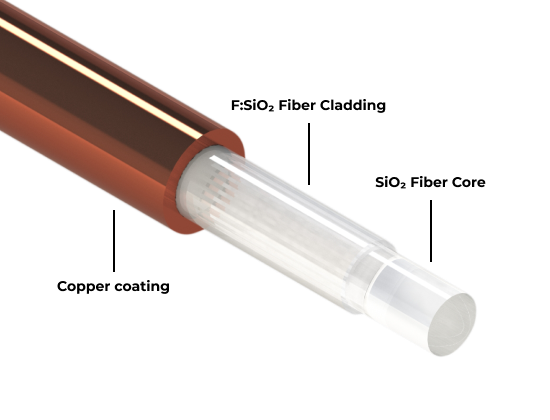

Mir Photonics’ Copper-alloy Coated Silica Fibers represent the pinnacle of fiber technology for applications exposed to extreme conditions, including very high temperatures, high vacuum, and harsh or demanding operational environments. Engineered to perform where conventional fiber solutions reach their limits, these fibers combine excellent optical stability with robust thermal and mechanical performance, making them well suited for industrial, scientific, and aerospace use cases.

These copper-alloy coated fibers retain all the key advantages of traditional silica-silica fibers, such as low optical loss, chemical stability, and consistent transmission characteristics. In addition, the metallic coating provides substantial improvements in mechanical strength and durability, as well as increased resistance to fatigue and mechanical stress when compared to polymer-coated fibers. This results in improved reliability and extended service life in applications involving vibration, repeated handling, or elevated thermal loads.

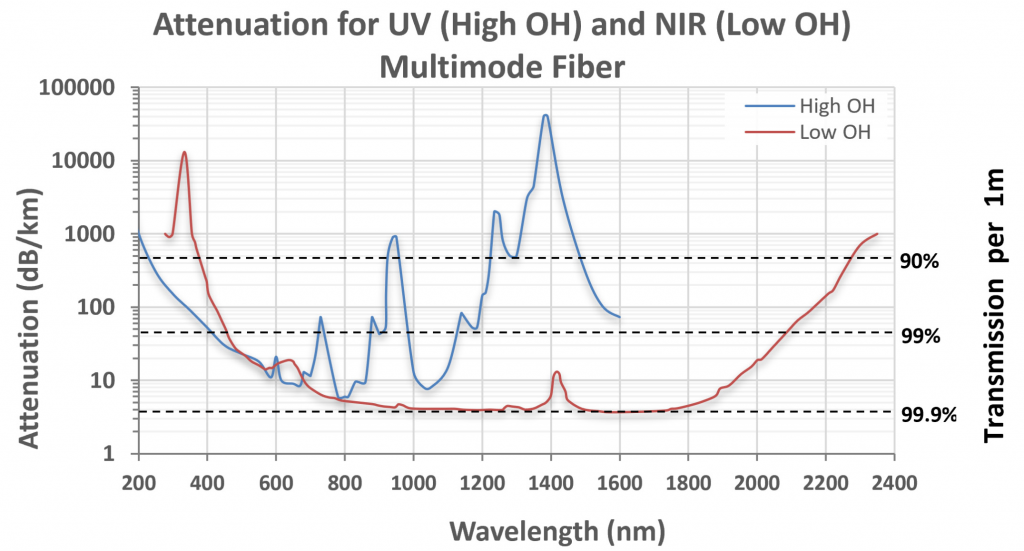

Their optical transmission spans a wide range from 220 to 2400 nm, depending on the choice of UV or NIR silica fiber cores, enabling use across a broad spectrum of optical and spectroscopic applications. Notably, these fibers maintain reliable performance across an extreme temperature range, from cryogenic levels down to –270°C up to continuous operation at temperatures as high as 600°C, while also tolerating humidity levels of up to 100% without compromising optical or mechanical integrity.

| Specification of Cu-alloy coated Fibers | |

|---|---|

| Core/ Cladding material Step Index | Pure Fused Silica Core / Fluorine Doped Silica Cladding |

| Graded Index | Germanium Doped Fused Silica Core / Pure Fused Silica |

| Fiber core diameters, μm | 9; 50; 62.5; 100; 200; 400; 600 |

| Cu-alloy coating thickness, μm | 15 – 50 (depending on fiber diameter) |

| Standard Numerical Aperture (NA) | 0.22 ± 0.02 |

| Available Numerical Aperture (NA) | 0.12 ± 0.02 0.26 ± 0.02 |

| Min operating temperature, °C | -270 |

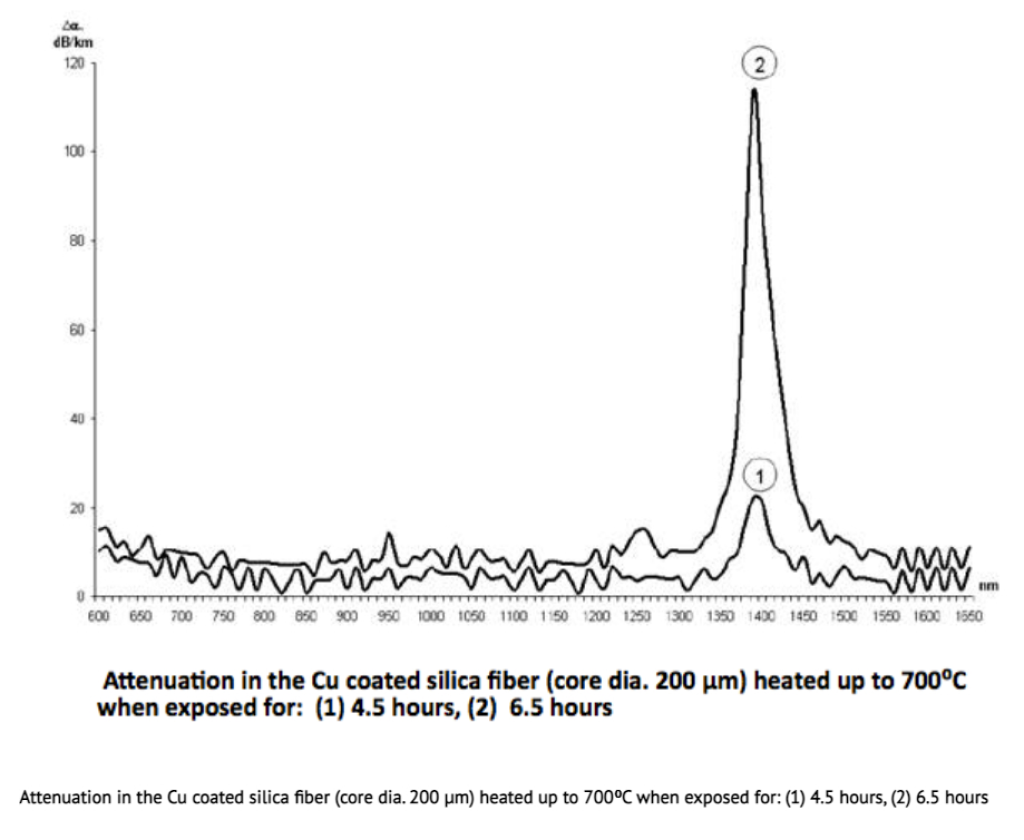

| Max operating temperature, °C | 600 |

| Humidity Range | Up to 100% |

| Minimal bending radius (long term) | 200 x fiber outer diameter |

| Minimal bending radius (short term) | 100 x fiber outer diameter |

| Tensile strength (short gauge), GPa | 3.5 – 6 |

| Two point bending strength, GPa | >10 |

| Static fatigue parameter | >100 |

| Parameters of standard Cu-alloy coated Fibers | |||||

|---|---|---|---|---|---|

| Code | Type | Core, μm | Cladding, μm | Coating Cu, μm | NA |

| 100/110 Cu | Step Index Multimode | 100 ± 2% | 110 ± 2% | 145 ± 5% | 0.22 |

| 200/220 Cu | Step Index Multimode | 200 ± 2% | 220 ± 2% | 270 ± 5% | 0.22 |

| 400/440 Cu | Step Index Multimode | 400 ± 2% | 440 ± 2% | 535 ± 5% | 0.22 |

| 600/660 Cu | Step Index Multimode | 600 ± 2% | 660 ± 2% | 745 ± 5% | 0.22 |

| 50/125 Cu | Graded Index Multimode | 50 ± 2% | 125 ± 2% | 165 ± 2% | 0.22 |

| 9/125 Cu | Single mode | 9 ± 5% | 125 ± 5% | 165 ± 2% | 0.13 |

High temperature environments

Harsh Chemical environments

Nuclear radiation resistant devices

Down-hole sensing for oil and gas industry

High Power Laser delivery

Medical applications

Soldered fiber bundles